top of page

Aerial Drone Inspection

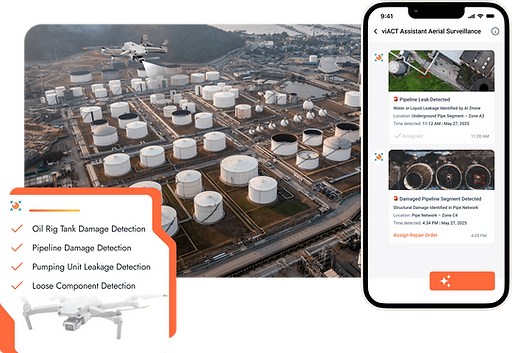

viAER: Unlock Total Site Intelligence with Drone AeroVision AI Technology

Scanning hazardous zones, capturing aerial visuals, and automating inspections from above — this AI-powered drone inspection takes site monitoring and workplace safety automation to the next level. Because when risks are hard to reach, viAER makes sure your eyes in the sky never miss a thing!

The most awarded Drone AeroVision AI Technology, Trusted by leaders!

.png)

Built for the Sky, Trusted on the Ground

viAER redefines industrial aerial monitoring with AI-powered drone inspections, keeping an eagle eye on your most critical, hard-to-reach assets, no matter how remote, elevated, or hazardous they are.

.png)

Heavy industrial sites

and yards

.png)

Tank farms and storage facilities

.png)

High-rise roofs, chimneys, and stacks

.png)

Bridges, gantries, and conveyor systems

.png)

Hazardous or hard-to-reach zones

.png)

Large-scale construction sites

.png)

Remote maintenance and inspection areas

.png)

Emergency aerial assessment zones

Complaint and Standardized

with industry Codes of Practice for

.png)

Construction

Logistics

Warehousing

Mining

Utilities & Energy

Manufacturing

Oil & Gas

Ports & Maritime

Operations

Vision still tied to the ground?

Take your site safety to new heights with viAct viAER — the AI-powered drone inspection technology compatible for wide range of drone types, giving your industrial assets the aerial advantage—faster, safer, smarter.

Don’t climb it. Fly it!

1

AI-Powered Autonomous Aerial Intelligence

viAER combines AI-powered analysis with automated drone data capture to deliver high-resolution insights in real-time. Drones operate autonomously to scan job sites without manual input, reducing operational costs. AI algorithms detect anomalies, predict maintenance needs, and deliver 99.9% accurate alerts, enhancing proactive decision-making. From spotting structural deviations in construction zones to detecting surface instability in mines or corrosion in offshore rigs, viAER helps teams act before issues escalate.

2

Unified Digital Twin & Reality Capture

By fusing aerial, ground, and fixed camera feeds into one intelligent platform, viAER creates a high-fidelity digital twin of the site. This unified reality capture offers unparalleled visibility and situational awareness, transforming how teams monitor, inspect, and plan across complex job sites. Whether it is visualizing container movements across ports, tracking vehicle flow in logistics yards, or mapping utilities infrastructure, teams gain a single pane of glass to manage operations.

3

Edge AI for Remote & Resilient Monitoring

Edge AI processing enables drones to analyze data on-device, ensuring uninterrupted performance in low-connectivity or remote environments. This guarantees real-time safety and progress updates even when cloud access is limited, making it ideal for dynamic, infrastructure-heavy zones. In remote mining sites, offshore platforms, and expansive energy farms, viAER ensures nothing is missed — even when network bars disappear.

4

Connected Collaboration & Scalable Integration

viAER’s collaborative platform integrates seamlessly with Smart Site Safety System, BIM, WMS, and ERP systems, streamlining workflows across stakeholders. Real-time annotations, measurements, and updates ensure that field and office teams stay aligned, accelerating decisions and improving compliance outcomes. From syncing project updates on construction sites to aligning warehouse inventory data in logistics, viAER bridges the gap between physical operations and digital command centers.

viAER Sky Advantage

Why choose viAER for Industrial Aerial Inspection?

.png)

Low Altitude Economy Compliant

Urban-Ready Drone Operations

Compliant with Hong Kong’s Low Altitude Economy Initiative; viAER by viAct autonomously inspects high-rise and urban sites under 1,000m without disrupting air traffic.

.png)

Predictive Automations for Large Projects

Precise Aerial Fault Forecasting

Supports smarter, automated infrastructure monitoring across oil fields, high-speed rail, utilities, and giga-projects, in line with Saudi Vision 2030 and guided by SDAIA’s national AI strategy.

.png)

Single Source of Truth

Seamless Aerial-Ground Integrated Reality

Aligning with Singapore’s IDD (Integrated Digital Delivery); viAER drone feeds are fused with fixed feeds to integrate work processes and connect stakeholders in construction sites.

.png)

Government-Grade Interoperability

Seamless National Platform Integration

With strict adherence to region-specific drone regulations and data privacy mandates, viAct drone inspection empowers project coordination with regulation-ready interface.

Drone or Delay?

When ground-bound AI inspections stall progress, viAER takes flight — delivering faster, smarter, and scalable oversight from above.

Without viAER

Relies solely on static ground cameras, limiting visibility in vertical and high-rise structures.

AI analysis restricted to fixed ground perspectives-missing anomalies at elevation.

Manual inspections require scaffolding, crane access, or lift equipment, causing delays.

Ground-only data leads to fragmented reporting, creating blind spots across project zones.

With viAER

Real-time aerial telemetry delivers full-structure visibility from elevation to edge.

Drone-mounted AI captures anomalies and progress deviations from all angles.

Zero-setup autonomous drone flights accelerate inspections and reduce downtime.

Fuses aerial and ground data into one cohesive visual layer; true Single Source of Truth.

Automating Inspection from Air to Asset: viAER at Work

Precise Geospatial Mapping for Quick Site Planning

Leverage drone inspection powered by viAER to produce high-precision 3D topographic maps and ortho-mosaics with centimeter-level accuracy, enhancing site planning and layout validation for construction, mining, and oil & gas industries.

.png)

.png)

Safety Compliance Monitoring for Large Projects

viAER drone inspection by viAct detects PPE compliance and unsafe worker behavior on-site for large projects, significantly reducing accidents and ensuring regulatory adherence across manufacturing, energy, and heavy civil construction sectors.

Automated Volumetric Earthwork Quantification

Perform rapid, precise volume calculations of earthwork stockpiles and cut/fill areas with drone inspection technology from viAER, enabling mining and construction operations to optimize resource allocation and improve project efficiency.

.png)

.png)

Autonomous Confined/Restricted Space Inspection

viAER enables drone inspection in confined, hazardous, or GPS-denied environments such as oil rig tanks, pipelines, and industrial plants, eliminating manual entry risks and ensuring comprehensive asset integrity checks for upstream oil & gas and heavy industries.

BIM-Integrated Progress Analytics for Complex Sites

Using drone inspection capabilities from viAER, construction progress is continuously monitored against BIM models, delivering real-time insights to identify delays, deviations, and workflow bottlenecks in construction and infrastructure projects.

.png)

.png)

Thermal and Visual Anomaly Detection

Integrate thermal and visual drone inspection powered by viAER to identify overheating motors, structural anomalies, or potential equipment failures, minimizing unplanned downtime and maintenance costs in manufacturing plants and downstream energy facilities.

Automated Perimeter Security Surveillance

viAER drone inspection automates perimeter patrols, detects unauthorized intrusions, and provides real-time security alerts, helping logistics hubs, warehouses, and industrial yards maintain strict access control and safety.

.png)

.png)

Rapid Incident Response Mapping

Rapid deployment of AI-powered inspection through viAER delivers emergency mapping of fires, spills, or structural collapses, providing detailed situational awareness that supports faster, safer incident response for construction, oil & gas, and energy sectors.

Automated Inventory Verification Systems

Automate inventory cycle counts and detect stock discrepancies with drone inspection solutions from viAER, significantly improving accuracy and operational efficiency in manufacturing plants, distribution centers, and logistics facilities.

.png)

Post-Deployment Impact: From Drone to Data

.png)

.png)

.png)

bottom of page

.png)

.png)