Mining Operator from Chile Cuts High-Risk Exposure by Over 65% Using viAct Dynamic Safety Zoning

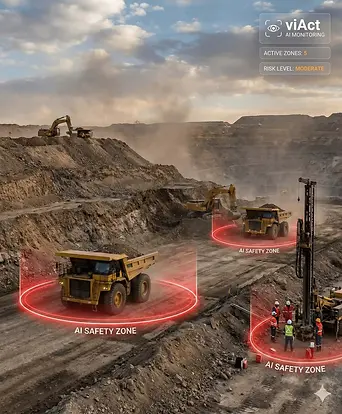

A leading mining operator in Chile managing large-scale, high-risk operations faced growing safety challenges from constant worker–vehicle interactions, mobile equipment, and rapidly changing work zones. Traditional static exclusion zones and manual supervision were no longer sufficient to prevent near-misses and zone intrusions around haul roads, loading areas, and active machinery. To overcome these challenges, the operator deployed viAct’s AI-powered dynamic safety zoning, transforming fixed safety rules into real-time, adaptive risk controls across complex mining environments.

70% Reduction in Proximity Risks

through Real-Time Dynamic Safety Zoning for Mining

65% Fewer Zone Intrusions

via Automated Detection across Active Mining Areas Sites

55% Faster Incident Response

enabled by Instant Alerts from Dynamic Safety Zones

Company Overview

A Chile-based mining operator with significant operations across Latin America manages large sites involving heavy haul trucks, mobile equipment, and constantly shifting work fronts. Operating in complex terrain, seismic activity, and extreme weather, company prioritizes worker safety, regulatory compliance, and uninterrupted production. Traditional static exclusion zones and manual supervision, however, struggled to reflect the dynamic risk conditions common across Chilean and Latin American mines. To address recurring risks from worker–vehicle interactions, zone intrusions, and limited visibility, the operator adopted viAct AI-powered solutions.

Story Snapshot

Manual monitoring created blind spots during shift changes and peak haulage periods. With viAct, safety zones became adaptive and real-time, enabling faster intervention, improved awareness, and risk control across mines.

Industry:

Mining

Location:

Chile

Use Case:

Dynamic Zone

The Challenge

Protecting workers as mining safety zones constantly shift

As this Chile-based mining operator expanded and optimized operations across Latin America, safety challenges intensified. Open-pit layouts changed frequently, haul routes shifted daily, and heavy mobile equipment operated alongside workers in high-risk zones. Supervisors struggled to enforce exclusion zones consistently as static safety boundaries quickly became outdated. Reliance on periodic inspections and manual monitoring meant critical risks—such as worker–vehicle proximity and unauthorized zone entry—often went unnoticed until near-misses occurred. With production targets tight and regulatory scrutiny high across the region, leadership needed a future-ready approach to deliver real-time visibility, eliminate safety blind spots, and maintain consistent safety standards across dynamic mining environments.

For leadership, the challenge went beyond compliance—it was about embedding proactive risk control into everyday operations. A digital, adaptive safety framework was essential to protect workers while sustaining productivity.

“Mining conditions here change hour by hour—routes, equipment, people. Static safety rules simply couldn’t keep up. viAct gave us real-time visibility and control, helping us standardize safety across our operations.”

Operations Head

Latin America Mining Operations

The Solution

Converting Dynamic Blast Zones into Enforceable No-Go Areas

To maintain strict control over blasting zones and high-risk geotechnical areas, the mining operator implemented viAct AI-powered monitoring to transform restricted zones into dynamically enforced no-go areas. As blasting schedules, slope stability conditions, and work fronts changed, safety boundaries were digitally defined and updated in real time. AI video analytics continuously monitored these zones, instantly detecting unauthorized entry by workers or vehicles and triggering immediate alerts to supervisors. This eliminated reliance on manual patrols and static barricades, ensuring that no intrusion went unnoticed even during peak operations or low-visibility conditions. All violations were logged with visual evidence in a centralized dashboard, creating clear accountability and enabling faster corrective action across sites.

“viAct gave us real-time control over blasting and high-risk zones. We could enforce no-go areas consistently, even as conditions changed hour by hour,” said the Safety Officer, Blast Zone A, Chile Mining.

Preventing Collisions Across Haul Roads and Loading zones

Across mining operations, worker–vehicle interactions on haul roads and loading areas create shifting risks. Static barricades fail as routes change, traffic density spikes, and operational cycles fluctuate. viAct enabled dynamic safety zoning by creating moving risk zones around active haul trucks and machinery, expanding or contracting based on speed, direction, and proximity. In loading, dumping, and crusher areas, high-risk zones activated only during live operations and deactivated automatically when paused, while real-time alerts detected unauthorized entry early, allowing supervisors to intervene before collision or crushing incidents occurred.

Managing maintenance and oversight with dynamic zoning

During live mining operations, maintenance crews often work near active equipment, while PPE requirements, weather disruptions, and congestion continuously alter risk levels. viAct enabled dynamic safety zoning by creating temporary safety zones around maintenance tasks, while monitoring adjacent operational areas in parallel. Zone access was validated against PPE and permit requirements, triggering alerts when non-compliant workers entered restricted areas. During dust, low visibility, or congestion, zones tightened automatically. All zone breaches were visualized on Enterprise Centralized Management Platform (ECMP) for enabling real-time escalation, accountability, and proactive safety planning across large, complex mine sites operations.

The Impact

Turning Safety Intelligence into Operational Value

The impact of viAct dynamic safety zoning extended well beyond risk reduction. By automating zone enforcement across haul roads, blasting areas, and maintenance activities, the mining operator reduced manual supervision, unplanned stoppages, and production delays. Fewer near-miss escalations lowered equipment downtime and avoided costly shutdowns during peak operations. Centralized digital records simplified audits and reduced administrative effort across sites. Over time, improved predictability enabled better shift planning, equipment utilization, and contractor coordination. These operational efficiencies translated into measurable cost savings, stronger insurance positioning, and greater financial resilience across Chilean and Latin American mining operations, without increasing headcount or compromising safety governance standards regionwide

“What surprised us most was the financial impact. Fewer disruptions, less downtime, and clearer accountability improved our cost control—not just safety.”

Operations Head

Latin America Mining Operations