top of page

Crane Safety Software

Crane Safety Software: Your Go-To Safety Solution for Every Lift

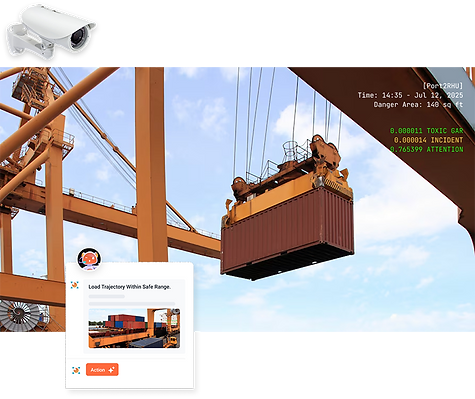

Through conversational AI and video analytics viAct Crane Safety Solution monitors load misalignments, and lifting behavior – enabling predictive maintenance for uninterrupted crane operations.

The most awarded EHS Management Platform, Trusted by leaders!

.png)

"

Crane blind spots were our biggest fear. viAct solved that with real-time monitoring and smart alerts. Zero downtime since!

"

- HSE Manager | Construction Industry

Our Technologies

Computer Vision

Transforms video feeds into actionable safety insights by detecting unsafe behaviors, PPE violations, and environmental hazards in real-time.

AI CCTV Cameras

Enhance traditional surveillance with AI-powered analytics to monitor compliance, detect intrusions, and automate safety alerts across dynamic jobsites.

Edge Devices

Enable real-time data processing on-site, minimizing latency and ensuring faster safety responses without relying on constant cloud connectivity.

IoT & Wearables

Integrates smart helmets, locks and sensors for seamless monitoring of workers’ vitals, movement, equipment status, and environmental conditions.

Drones

Deploy low-altitude drones for autonomous site surveillance, thermal scanning, and hazard detection in hard-to-reach or high-risk work zones.

Co-pilot / AI Agents

Acts as digital assistants offering voice/text-based safety guidance, process automation, and instant access to documentation for frontline teams.

What difference does Crane Safety Software makes?

IDENTIFY

Rigging Setup Errors

viAct Crane Safety System leverages Computer Vision and Edge AI to detect incorrect slinging, improper load angles, and unstable rigging setups; flagging 97% of critical rigging issues before lift initiation.

EVALUATE

Crane Performance & Maintenance Gaps

Crane Safety System analyzes processed data from real-time monitoring to evaluate crane performance, uncover hidden inefficiencies, and predict maintenance needs, reducing safety incidents by 90%, and ensuring smooth operations.

ENSURE

Predictive Safety Assurance

Leveraging AI video analytics, Crane Safety System ensures ongoing crane safety by forecasting potential issues, enabling proactive maintenance schedules that enhance operational continuity and reduce downtime.

You Handle the Load. We Handle the Warnings.

viAct Crane Safety Software brings clarity to every lift, flagging rigging faults, swing risks, and slip-ups before they escalate into hazards.

Spot Early. Lift Easy!

Key features of

Crane Safety Software

Risky Lifts Detection

Unsafe Load Swing Detection: Computer Vision tracks and flags abnormal load sway or uncontrolled motion in real-time, mitigating drop and collision hazards.

Load Angle Monitoring: Analyzes hook angles to validate vertical alignment, preventing tilted lifts, reducing structural strain, and maintaining mechanical stability during crane operations.

Overload Prevention: Detects excessive load weight before hoisting, preventing structural stress, cable failure, and safety violations; ensuring compliant, damage-free lifting every time.

.png)

Pre-Lifting Inspection Automation

Hook & Shackle Integrity Check: Edge device (viMAC) scans sling hooks and shackles for wear, cracks or incorrect attachment before lifting.

Zone-based Safety Validations: Ensures lifting zones are clear of unauthorized personnel or obstructions using AI CCTV.

Permit Sync: Verifies ePTW clearance and logs safety checks before crane operations begin.

viHOI for Hoisting Hazard Detection

Rope Slack & Drift Monitoring: Detects rope looseness and side drift, indicating unstable lifts.

Proximity Violation Alerts: Detects unsafe worker movements near live hoisting zones and sends instant alerts to operators/ supervisors.

Incident Video Capture: Automatically records unsafe lifts or emergency halts for review, training, and compliance documentation.

Zoning & Geofencing Intelligence

Boom Collision Avoidance: Continuously monitors crane-to-crane and crane-to-object distances using Edge AI, ensuring safe clearances and preventing collision.

Dynamic Geofencing: Adjusts lifting zones in real-time based on weather, type of load, or surrounding activity.

Operator Behavior & Distraction Monitoring

Fatigue-Based Control Drift: Detects early signs of operator fatigue like lagging response or erratic joystick control, triggering real-time alerts to prevent mishaps.

Cabin Inattentiveness Detection: Monitors in-cabin posture and eye movement to prevent distraction during lifts.

Unauthorized Crane Use: Flags and reports crane access outside approved shift timings or without digital permits.

Post Deployment Performance Matrix

95%

Reduction in crane-related safety incidents caused by overload, swing, or rigging failures through real-time hazard detection.

80%

Lesser lifting errors through AI-based alignment and load balance checks, improving lift precision.

10X

Lower insurance & legal risks through reduced incidents, better documentation, and proactive compliance prevention.

Unique Value Prepositions

Edge AI Crane Control

Leverages Edge AI for real-time analysis of crane operations, minimizing cloud reliance, accelerating response, and proactively mitigating rigging or load-handling risks.

Crane Vision Intelligence

Combines swing tracking, rigging inspection, and zone breach detection using Vision AI for instant alerts, precise lifting, and enhanced crane safety.

IoT-Powered Crane Surveillance

Crane Safety Solution leverages IoT sensors to monitor load paths, operator behavior, and machine health, ensuring data-backed precision and risk detection.

AI Crane Co-Pilot

Empowers crane operators and EHS teams with 100+ Vision AI Agents analyzing lift performance and recommending predictive safety/maintenance actions.

Responsible AI

Ensure Responsible AI for crane operations through secure data protocols, transparent alerts, and alignment with industrial safety and privacy standards.

Ask Our Expert

Common questions our AI experts have been asked by EHS professionals about

Crane Safety Software . Don't hesitate to ask us your question!

What is viAct Crane Safety Software and how does it improve lifting safety?

Crane Safety Software by viAct uses Computer Vision and Edge AI to monitor rigging angles, load stability, and surrounding activity in real-time. It flags anomalies such as swaying, slacking, and overloading before they become incidents, making every lift safer, faster, and compliant.

How does the Crane Safety System help prevent collisions and blind spot accidents?

The Crane Safety System processes video feeds using AI video analytics and IoT-powered sensors to detect crane-to-crane and crane-to-object proximity. With dynamic geofencing and real-time alerts, it ensures safe clearances, especially in tight or congested sites.

Can viAct Crane Safety Solution assist in crane hoisting operations?

Yes. viHOI by viAct is an AI-powered solution designed to enhance safety and efficiency in hoisting operations within construction and industrial environments. It utilizes advanced AI computer vision to monitor, analyse, and improve lifting activities in real-time. It detects improper hooking, rigging slips, and unsafe operator behaviour, triggering instant alerts and logging footage for training and compliance.

Is data from the Crane Safety Software secure and compliant with industry regulations?

Absolutely. All data captured through AI CCTV and IoT devices is processed at the Edge – limiting cloud exposure, and stored securely with access control. Generative AI is used only for insights and recommendations, ensuring privacy, traceability, and regulatory alignment.

What are the operational benefits of using viAct Crane Safety Solution?

By automating lift monitoring, incident capture, and safety analytics, Crane Safety Solution by viAct reduces downtime, improves operator response time, and cuts manual inspection efforts by up to 90%. The result? Safer cranes, smarter teams, and stronger ROI.

bottom of page