Marine-Grade AI Safety by viAct enhances Operational Discipline in Hong Kong’s Port Operations

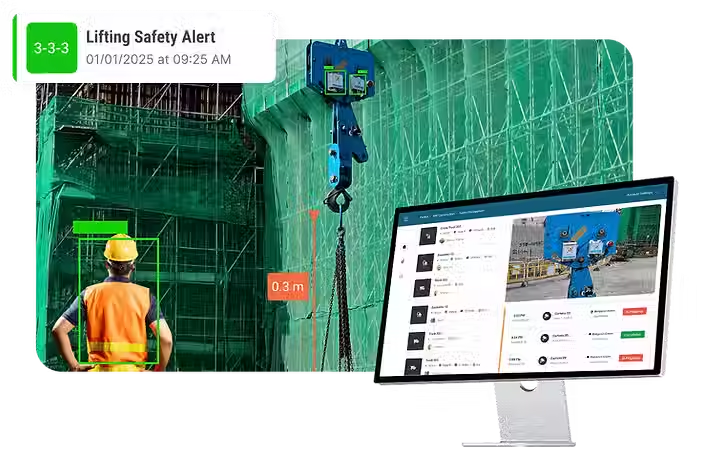

At Hong Kong’s Kwai Chung Container Port, one of the busiest terminals in Asia, operators faced growing risks of fatigue-related errors, near-misses in congested yards, and unsafe crane operations. Despite strict Marine Department safety codes, enforcing the 3-3-3 lifting protocol and monitoring suspended load zones proved challenging. To strengthen frontline safety, the operator adopted viAct’ AI-powered Port Safety Package, combining fatigue monitoring, lift zone intrusion alerts, proximity breach detection, and digital permit-to-work for full compliance.

10× Improvement in Lift Zone Safety Score

with monitoring of suspended load areas.

60% Drop in Fatigue-Linked Errors

by monitoring crane & yard operators in action.

50% Improvement in Yard Productivity

through fewer incident-related stoppages.

Project Overview

Hong Kong’s Kwai Chung Container Port is the busiest logistics hub in Asia and a major role player in Hong Kong’s position as a global trade leader. The terminal operators handle thousands of container movements daily with round-the-clock crane operations. Facing increasing risks around lifting zones in high-traffic yards, operators sought a smarter way to protect workers and assets while meeting regulatory compliance.

Story Snapshot

With nonstop crane operations and heavy container traffic, Kwai Chung Port faced challenges enforcing lift zone protocols. Manual checks missed suspended load breaches, fatigue signals, and access violations. By adopting viAct AI Safety Package comprising of lift zone monitoring, fatigue alerts, PPE detection, and digital PTW, the port achieved Marine Department compliance, reduced downtime, and improved overall safety efficiency.

Industry:

Port & Logistics

Location:

Hong Kong

Use Case:

Crane Safety AI

The Challenge

Managing lift zone safety across nonstop crane operations

At Hong Kong’s Kwai Chung Port, container handling never stops. Heavy crane operations, suspended loads, and dense worker activity made lift zones one of the most hazardous areas on site. Despite established safety rules, supervisors faced persistent blind spots: workers drifting too close to suspended cargo, fatigue impacting crane operators, and unauthorized access into high-risk areas. Traditional monitoring methods—manual patrols, paper-based permits, and sporadic reporting—were reactive and often identified risks only after unsafe events had already occurred.

Leadership realized these fragmented practices slowed down incident response and created gaps in compliance with the Marine Department’s rigorous safety standards. Incremental fixes were not enough. The port urgently needed a proactive, always-on system to safeguard workers, maintain operational flow, and deliver measurable improvements in safety oversight at scale.

“I’ve spent two decades in port operations, and crane lifts over busy yards have always been stressful. viAct AI changed that with real-time alerts and digital oversights. I finally go home knowing our people are protected.”

Senior Yard Supervisor

Kwai Chung Port

The Solution

Unifying Port Safety with AI-Powered Oversight

To tackle fatigue-related errors, near-misses in congested yards, and unsafe crane operations, the port operator implemented viAct AI-powered Port Safety Package across Kwai Chung Terminal. By integrating fatigue monitoring, lift zone intrusion alerts, proximity breach detection, and digital permit-to-work into a single platform, supervisors gained real-time visibility into every critical operation. The system converted traditional surveillance into intelligent oversight, continuously updating dashboards that reflected compliance with Marine Department safety codes and adherence to the 3-3-3 lifting protocol.

“viAct centralized platform transformed our approach to safety, giving us live insights into fatigue levels and high-risk lift operations. We can now proactively prevent incidents rather than react after the fact,” said the Senior Yard Supervisor.

“With automated alerts for lift zone intrusions and proximity breaches, our teams are more confident operating in congested areas. Compliance reporting is now instant, audit-ready, and fully transparent, saving time and avoiding potential penalties,” added the Port Operations Manager of Kwai Chung Port.

AI-powered fatigue detection for crane and vehicle operators

To complement lift zone safety, the port deployed the viAct fatigue monitoring module for crane and yard vehicle operators. The AI analyzed micro-expressions, blink rates, and head movements through existing cabin cameras, detecting early signs of drowsiness or distraction. When fatigue indicators crossed safe thresholds, real-time alerts were issued to both operators and supervisors, enabling immediate intervention.

By shifting from reactive incident response to proactive health and safety monitoring, the port significantly reduced fatigue-related near misses and equipment handling errors in high-traffic zones.

Automated compliance with the 3-3-3 lifting protocol

Building on intelligent lift zone monitoring, the port integrated AI to ensure every crane lift followed the 3-3-3 protocol, lifting loads 0.3m, holding steady for 3 seconds, and enforcing a 3m worker clearance. The system automatically verified each step, triggering alerts if stability checks or distance rules were breached.

“Earlier, confirming compliance relied on supervisors’ judgment. Now the AI validates it in real time, leaving no room for error,” said the Crane Operations Lead. “It’s the first time we’ve had assurance that every lift meets the Marine Department’s gold safety standard,” added the Port Operations Manager.

The Impact

Building long-term safety resilience with viAct AI

For Kwai Chung Port, viAct AI system extended its influence well beyond operational safety. The platform’s automated compliance logs streamlined marine audits, cutting administrative hours while ensuring transparency with regulators. Long-term data insights provided benchmarks for continuous improvement, supporting both ESG disclosures and stakeholder confidence.

The visibility of proactive lift zone and fatigue monitoring also strengthened trust with international shipping clients, positioning the port as a forward-looking, technology-driven operator.

By turning safety into a measurable competitive advantage, viAct enabled sustainable growth, reduced risk exposure, and enhanced the port’s global reputation.

“In 6 months, viAct reshaped yard culture, and workers became more proactive, prioritizing safety as part of daily routines.”

Senior Yard Supervisor

Kwai Chung Port