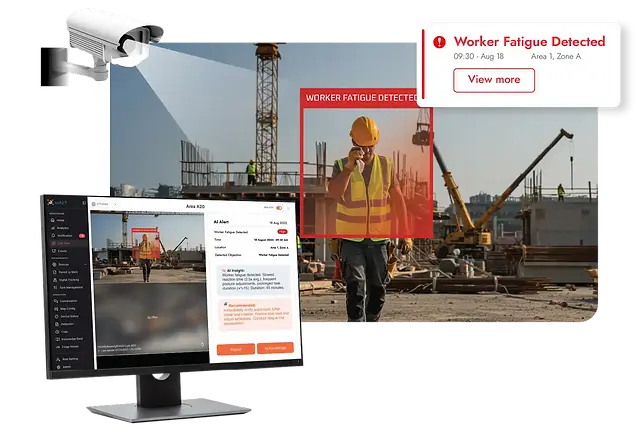

Worker Fatigue Detection

Reducing Fatigue-Driven Safety Risks and Delays with AI-Powered Worker Fatigue Detection

Fatigue quietly undermines safety and output on industrial sites. As alertness declines, reaction time slows and errors increase, near-miss potential raises – especially around moving equipment, and repetitive tasks. AI-enabled Worker Fatigue Detection upgrades existing CCTV cameras to flag early fatigue cues for timely action.

Worker Fatigue Detection is a Vision AI solution that identifies fatigue indicators by observing human behavior patterns, like prolonged stillness, slowed pace, reduced head/torso stability, repeated micro-pauses, or diminished task engagement. In manufacturing plants, warehouses, process facilities, and large industrial yards, fatigue can build gradually across shifts, making it difficult to identify through periodic checks or supervisor rounds.

Powered by viAct AI video analytics, the solution continuously analyzes CCTV streams to flag fatigue-like behaviors in workplace. Instead of relying on self-reporting or manual supervision, it provides consistent monitoring across multiple areas and shifts, including nights or high-volume periods. When risk patterns emerge, it supports faster decisions – rotate tasks, trigger supervised breaks, or suggest manpower allocation adjustment.

With real-time alerts, incident logs, and trend reporting, the AI-enabled Worker Fatigue Detection solution helps EHS and operations teams curb fatigue-related errors, strengthen compliance documentation, and sustain productivity, without adding supervisory workload or increasing surveillance headcount across shifts and site zones.

Why Is Fatigue Management So Difficult on Industrial Sites?

Most workplaces recognize fatigue as a risk, yet it persists because it is operationally complex. Output pressure, overtime, understaffing, and variable workloads create conditions, where tired workers continue operating, often without raising a flag. Meanwhile, supervisors may oversee multiple zones, and fatigue cues can be subtle, intermittent, and easy to misinterpret.

Common fatigue-driven risk situations include:

● Missed visual/audio cues in high-noise, high-activity work zones

● Slower reactions while working near moving machinery or vehicle routes

● Incorrect tool or control handling during routine, repetitive operations

● Delayed response to alarms, spotters, proximity warnings

● Unsafe manual handling posture leading to drops, strains, or pinch incidents

● Reduced balance or missteps on stairs, ramps, or uneven walkways

● Task sequencing mistakes causing rework, stoppages, or quality deviations

● Momentary loss of attention leading to missed hazards and near-misses

Fatigue often begins as minor performance decline but can quickly translate into unsafe choices and costly disruptions.

Even with policies and toolbox talks, fatigue can go unseen between checkpoints, especially across large sites, night shifts, or peak workloads. viAct Fatigue Detection module applies AI video analytics to deliver continuous visibility through existing CCTV cameras, helping teams detect fatigue-linked patterns early, prioritize interventions, and act before incidents, quality errors, rework, or operational delays occur.

Where Does Worker Fatigue Detection Deliver Most Value?

Worker fatigue affects every industry where long shifts, physical strain, and sustained attention are required. It is most critical where tiredness can trigger serious injury, process deviation, or production disruption.

Oil & Gas Offshore and Onshore Rig Operations

On offshore and onshore rigs, fatigue can degrade judgment during inspections, isolations, and routine process tasks. Vision AI-powered Worker Fatigue Detection pinpoints fatigue cues around process units and operator interfaces, prompting rapid checks to prevent errors, incidents, and avoidable unplanned downtime.

Construction and Infrastructure Work Zones with High Task Variability

Heat stress, harsh site conditions, and physically demanding tasks can accelerate fatigue across crews. AI monitoring provides continuous coverage across dispersed work fronts, signaling fatigue-linked slowdowns or instability early to support safer execution, fewer near-misses, and reduced stoppages.

Mining, Remote Yards, and Heavy Industrial Sites

In mining and heavy-industry yards, fatigue can accumulate during repetitive equipment cycles and isolated work fronts. Automated Worker Fatigue Detection reveals subtle behavioral decline, enabling focused checks that reduce human-error events and lower incident likelihood during lifts, hauling, and maintenance activities.

Maritime Terminals and Portside Cargo Operations

Port operations run continuously, leaving little margin for lapses in vigilance. Computer vision-enabled Worker Fatigue Detection identifies fatigue-like behavior across crane cabins, quay edges, yard lanes, and gate checks, reducing dropped-load exposure, traffic conflicts, procedural lapses, and delayed hazard response.

Manufacturing, Warehousing, Distribution Centers & Logistics Operations

High-volume production and fulfilment depend on steady pace and precision, yet fatigue can gradually reduce both. AI-powered Worker Fatigue Detection detects slowdowns, posture instability, and attention drift, enabling rotation and micro-breaks that cut defects, picking mistakes, near-misses, and unsafe equipment handling.

How Does Computer Vision Detect Worker Fatigue?

1

Choose

EHS teams can select the “Worker Fatigue Detection” module from viAct’s viHUB – a centralized hub of 200+ AI video analytics modules. The module continuously monitors and detects behavioral and physical indicators associated with fatigue across diverse work settings.

2

Connect

Worker Fatigue Detection module connects directly with existing CCTV/ IP cameras via RTSP link, enabling rapid deployment without additional hardware, complex system reconfiguration, or operational disruption across active industrial environments.

3

Capture

Once enabled, the AI continuously evaluates live video feeds for fatigue-related patterns, such as the following observable behaviors across monitored work zones and shifts in real-time:

● Prolonged slouching or static posture

● Repeated pauses and task interruptions

● Reduced focus and slower responses during active operations

4

Control

When fatigue risk thresholds are crossed, the system sends out automated alerts to supervisors via dashboard and mobile app, paired with on-site indicators. It also records events and generates trend reports, supporting fatigue management planning, targeted interventions, shift optimization, and audit-ready documentation for internal reviews or regulatory compliance.

Case Study: Yokohama Manufacturer Cuts Collisions Linked to Forklift Operator Fatigue with viAct Worker Fatigue Detection Solution

Industry :

Manufacturing

Location :

Yokohama, Japan

Module :

Worker Fatigue Detection

The Problem:

A Yokohama-based manufacturer with dense aisle traffic and frequent pallet movements saw risk clustering around forklift maneuvers near racking ends, crossings, and dispatch lanes - most notably late in the shift. Supervisors could not consistently identify operator tiredness early enough, increasing bump, strike, near misses and collisions.

The Solution:

viAct Al-powered Worker Fatigue Detection was deployed on existing cameras covering forklift corridors and dock approaches. It identified declining operator alertness and notified shift leaders, enabling check-ins, short pauses, and reassignment of higher-risk runs while maintaining logistics flow.

The viAct impAct:

● Within six months, fatigue-linked forklift collisions and near-misses reduced by 80%, and shift performance consistency improved across critical logistics zones.

● The solution strengthened audit readiness and supported proactive EHS controls for forklift operations across shifts and zones.

Why Choose viAct AI-enabled Worker Fatigue Detection Over Traditional Approaches?

AI-based fatigue monitoring strengthens existing fatigue management practices by adding continuous, measurable visibility that scales with operations.

01

Automates fatigue screening across cameras 24/7, reducing manual patrol rounds and improving coverage across multiple zones and shifts by 3X.

02

Alerts supervisors immediately when fatigue cues persist, enabling timely breaks, rotation, or task reassignment.

03

Creates time-stamped evidence with video clips, streamlining investigations, supervisor coaching, and corrective actions, while supporting audit trails and compliance documentation.

04

Cuts detection-to-action time from minutes to seconds, reducing fatigue-driven errors near machines, vehicles, and lifts by 85%.

05

Maintains continuous fatigue visibility during night shifts and peak workloads, when supervision is stretched, helping prevent overlooked risk buildup.

06

Lowers downtime from fatigue-linked mistakes by 80%, sustaining throughput and quality during extended, high-demand production cycles.

07

Integrates with existing CCTV and dashboards, scaling across new zones without hardware, while standardizing fatigue oversight for contractors, shifts, and multi-site operations.