Video Analytics Solution

Less Accidents, More Visibility – Computer Vision Solutions built for Heavy Industries

From AI CCTV to IP Cameras—Video Analytics Software by viAct leverages AI-powered Computer Vision to deliver intelligent safety surveillance that doesn’t just observe but actively protects your people, assets, and operations. through 24/7 with real time onsite/offsite alerts/alarm of safety violations and active hazards, helping EHS teams to improve compliance and elevate workplace safety & productivity.

The Most Awarded Video Analytics Solution, Trusted by leaders!

.png)

Turning Cameras into Safety Guardians with Video Analytics for Heavy Industries

Partner for your Safety Teams that never blinks but always thinks!

Construction

Detects unsafe behaviors, PPE violations, and site hazards in real-time, keeping your construction jobsites compliant and accident-free.

Logistic & Warehousing

Tracks vehicle movement human-machine interaction, and zone breaches to prevent collisions and streamline logistic operations.

Utility & Energy

Detects arc flash risks, electrical panel violations, and unauthorized access to critical zones; reducing hazards and ensuring uptime in energy facilities.

Oil & Gas

Monitors restricted zones in oil & gas industry like rigs and flammable areas precisely, minimizing risk and ensuring safety in high-pressure environments.

Mining

Provides visibility in dusty hazardous mining environment for detecting violations and near misses before they become disasters

Chemical

Monitors PPE compliance, spill zones, and restricted handling areas; preventing exposure, contamination, and regulatory penalties in chemical industries.

Manufacturing

Automates detection of unsafe practices and machine-related risk to reduce downtime and protect frontline workers in manufacturing floors.

Port & Maritime Operations

Monitors cargo zones, loading activities, and restricted access in real time to prevent accidents and unauthorized entries in port.

Built For Safety Leaders

For Safety Executives

Turn multi-site chaos into one trusted safety score.

Helps in building regulations with video analytics by unifying all sites with real-time safety scores, verified data, and one AI-powered dashboard you can trust.

For Operations Leaders

Turn scattered issues into structured insights.

Helps to track where time and efficiency are lost using computer vision powered workforce heat maps, enabling faster fixes, lower downtimes, and smarter cost control.

For Frontline Workers

Turn risky moments into real-time protection.

Helps you work with confidence, knowing our video analytics solution alerts you of the minutest of risks in real-time so that you can head home safe.

How It Works?

From Camera Feed to Intelligent Action

The Video analytics software system is completely hardware agnostic, so you can plug in and go with your existing camera systems to improve safety.

Choose

Pick from 100+ AI modules in viHUB to detect critical safety issues or non-compliances onsite.

Connect

Easily integrate with your existing AI CCTV, AI Camera, or IP Camera via RTSP—no new hardware needed.

Capture

Our AI Video Analytics instantly detects risks from live footage.

Control

Receive instant alerts (onsite/offsite) and access an intuitive dashboard for daily/weekly/monthly safety reports for data-driven decisions.

Make Informative Safety Decisions

The video analytics solution empowers safety executives, operations leaders & frontline workers with clarity, control, and confidence.

Safety Score

Fewer risky behaviors, higher your score; it’s that simple.

Mixes TRIR, DART & LTI into one powerful pulse check on safety.

Flag severe incidents (SIFs) before they hit the red zone.

Turns injury statistics into a single, meaningful score.

Safety Trend Reports

Know what’s recurring before it becomes a repeating danger.

Tracks repeated non-compliances across time, site & teams.

Visualizes spikes in risky behaviors to focus your fixes.

Transforms past data into dashboard foresight for future safety actions.

Site Wise Scorecards

Pinpoint where safety thrives and where it needs backup.

Compare safety performance across sites in real time.

Spot risk-prone locations, activities, or teams at a glance.

Track improvements or red flags to steer focused interventions.

Core Capabilities of Video Analytics Solution

Structured by What Matters Most on Site

PPE Monitoring

Ensure strict PPE compliance to reduce injury risks and enforce safety protocols in real-time.

Hard Hat Detection

Safety Reflective Vest Detection

Face Mask Detection

Face Shield Detection

Apron Detection

Eye Protection Detection

Gloves Detection

Coveralls/Protective Suits Detection

Ear Muff Detection

Safety Harness & Lanyard Detection

Behavior & Situational Safety

Analyze unsafe behaviors for root cause analysis and proactive accident prevention.

Running in Restricted Areas

Jumping over Barriers/Conveyor Belts

Bypassing Safety Gates/Guardrails

Unsafe Stairway Usage (Rushing/Slipping)

Improper Ladder Usage

Unsafe Machine Operation

Horseplay/Aggressive Movements

Loitering in Restricted Zones

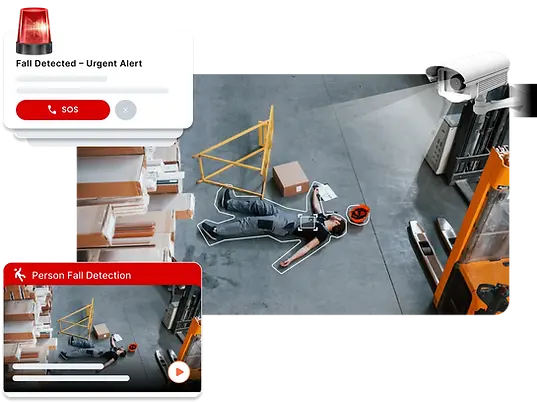

Falling Detection

Panic Movement in Crowds

Area Controls

Secure restricted zones to prevent unauthorized access and maintain operational integrity.

Unauthorized Entry into Restricted Zones

Access Without Proper PPE

Loitering In High-Risk Areas

Tailgating Detection

Overcrowding in Confined Spaces

Access During Non-Working Hours

Hazardous Zones Entry Without Permit

Shutdown/Maintenance Zone Access Monitoring

Unattended Person in Critical Zone

Vehicle Access to Pedestrian Areas

Ergonomics Monitoring

Promote proper posture and movement to minimize injuries at work and improve worker wellbeing.

Improper Lifting Posture

Repetitive Bending or Overreaching

Twisting while Carrying Loads

Unsupported Overhead Work

Prolonged Static Standing or Sitting

Slouching at Workstations

Overexertion/Overuse Detection

One-Arm Repetitive Task Detection

Incorrect Push/Pull Mechanics

Manual Material Handling Stress

Vehicle-Machine Control

Enhance site safety by controlling machine use, detecting operator risks, and preventing collisions.

Unauthorized Vehicle/Machine Use

Human-Machine Interaction

No Seatbelt Detection

Overspeeding in Site Zones

Blind Spot Near-Miss Detection

Driver Fatigue/Distraction Detection

Unsafe Forklift Operation (Speed/Turns)

Proximity Alert Near Pedestrians or Assets

Unsafe Machine Zone Entry

Automatic Number Plate Recognition

Housekeeping & Hygiene Monitoring

Maintain clean, hazard-free environments to reduce slips, trips, and regulatory non-compliance.

Floor Clutter/Trip Hazard Detection

Spill/Liquid Leak Detection

Blocked Emergency Exits or Pathways

Trash Overflow Detection

Improper Chemical Storage

Tools/Materials Left in Active Work Zones

Dust/Debris Accumulation Alerts

Wet Floor Without Signage

Open Trash Bins

Unsafe Stacking of Items

Detect real scenarios.

Deploy with ease.

Protect with trust.

What Makes Us Unique!

Proprietary Scenario-Based AI

Smart Video Analytics Software with Computer Vision is used to identify most complex micro actions rather than just detect object.

Proven on 300+ Projects across Verticals

viAct Video Analytics Software has been adopted worldwide by safety officers & EHS teams for high accuracy detections with low false alerts.

Privacy First Approach

Privacy-by-design Video Analytics Solution with face masking, encryption & on-premise deployment for AI CCTV in heavy industries.

100+ Pre-built AI Modules

Industry-tailored modules pre-trained on industry-specific hazards & non-compliances, built from real incidents in heavy industries, not simply generic datasets.

Quick & User Friendly Integration

Plug-and-play Video Analytics Software enabling rapid, no-code integration across existing CCTV systems and get safety insights on an intuitive dashboard.

Responsible AI

Ethically designed Computer Vision platform promoting safe and compliant AI usage for safer, productive & sustainable industrial workplaces.

Precision Safety Video Analytics for Unpredictable Scenarios

Cameras that analyze. Safety that scales!

Proximity Detection & Warning

An advanced AI camera solution that sets up virtual proximity zones around machinery, vehicles & restricted or high-risk areas. When video analytics software detects a breach, immediate alerts are issued, minimizing collision risks in oil & gas, manufacturing plants, warehouses, and construction zones.

Unauthorized Intrusion/ Danger Zone Entry Detection

This video analytics solution monitors access to restricted or hazardous areas. AI powered CCTV systems instantly flag unauthorized personnel entries, helping heavy industries enforce safety compliance and site security effectively.

Through intelligent computer vision, the system recognizes sudden posture changes or collapses. This AI-powered video analytics software for safety enables quick incident response in workplaces like oil refineries, mining sites, and construction zones.

Near Miss Detection

The AI video analytics software solution captures and analyzes close-call incidents—such as near collisions or slips. The data empowers safety teams to refine SOPs, improving site safety outcomes across high-risk operations.

Theft Detection

An ideal video analytics solution for theft prevention in warehouses, logistics hubs, and industrial storage zones, that uses AI CCTV and IP cameras to monitor irregular movements and suspicious activities around valuable assets.

Workforce Heat Maps

This video analytics software leverages computer vision to create real-time heat maps of worker movement and density, essential for resource planning and managing crowding in heavy industries like manufacturing, construction, and shipyards.

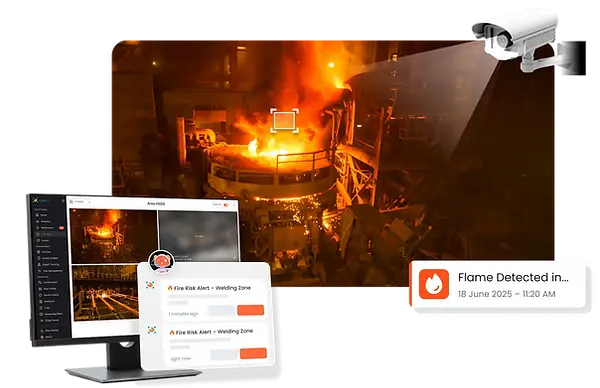

Fire, Smoke & Wildfire Detection

An intelligent safety video analytics application that detects smoke and flame signatures using AI camera feeds; especially valuable for heavy industries in wildfire-prone or flammable work environments, ensuring faster emergency response.

Proven Impact After Deployment

Video Analytics Solution empowers safety officers with real time data and corresponding proof

of breaches, enabling them to manage EHS better and reduce workplace injuries as a result.

90%

Less Mannual Inspections, No Site Visit & Ensures Remote Monitoring

80%

Drop in Repeated PPE Non-compliance Violations

10x

Audit Readiness with Safety Score and Trend Report

Reviews

Voices from the Field: Impact That Matters

viAct video analytics solution helped us enforce safety without micromanaging. With over 100 AI modules, it covered every scenario our dynamic site faced — from height work to lone worker safety.

Site Manager

Construction Contractor, Japan

Safety compliance monitoring used to be a manual nightmare. With viAct, the AI modules automatically adapt to different warehouse scenarios. It’s like having an extra safety officer who never sleeps.

Operations Head

Warehouse,

USA

What impressed us was the scenario-based detection. It didn’t just spot missing helmets — it understood the context. This level of intelligence is why we trust viAct across multiple factory zones.

HSE Lead

Manufacturing Plant,

Mexico

We chose viAct for our Berlin distribution center after evaluating similar platforms. What stood out was the depth—100+ AI modules and scenario-based detections tailored to fast-moving warehouse zones.

EHS Manager

Logistics Hub,

Berlin

We’ve deployed viAct's computer vision system in a hybrid setup—part cloud, part on-prem. It's incredibly flexible and scalable. Over 300 successful deployments gave us the confidence.

Safety Supervisor

Oil & Gas Facility,

UK

-

How can I implement viAct’s Permit to Work software at my worksite?viAct offers a cloud-based deployment that allows quick implementation without heavy IT infrastructure. It needs RTSP link of the existing CCTVs to load the AI modules. Nevertheless, You can request a demo to see how it fits your organization’s safety needs. Contact viAct’s team today to schedule a consultation.

-

Can viAct’s ePTW software track permit expiration and renewals?Yes, the digital PTW software of viAct includes an automated tracking system that notifies responsible personnel about permit expirations, pending approvals, and renewals to prevent unauthorized work and safety risks.

-

How does viAct’s PTW Software automate permit approvals?viAct's ePTW software automates the PTW process using AI and workflow automations, allowing seamless permit requests, multi-level approvals, and real-time tracking eliminating manual paperwork, speeds up approvals, and ensures compliance with OSHA, ISO, and industry standards.

-

Can advance PTW System by viAct integrate with existing safety management systems?Yes, viAct’s cloud-based PTW software integrates seamlessly with existing EHS (Environmental, Health, and Safety) management systems, ERP solutions, and compliance frameworks. It supports API integration for easy data exchange.

-

Who is viAct’s Permit to Work (PTW) Software designed for?The ePTW software by viAct is designed for safety managers, EHS officers, project supervisors, and frontline workers who handle high-risk tasks. It is widely used across industries such as construction, oil and gas, manufacturing, mining, and logistics. Whether it's site managers overseeing compliance, rig supervisors managing hazardous tasks, or plant operators ensuring safe work environments, the software simplifies the permit process, reduces risks, and enhances overall workplace safety. Its intuitive interface and AI-driven automation make it easy for teams at all levels to streamline permit approvals and maintain compliance effortlessly.

-

How does ePTW software by viAct help with regulatory compliance?viAct’s electronic PTW software ensures compliance with OSHA, ISO 45001, and other industry safety regulations by providing automated documentation, real-time monitoring, and audit-ready reports. It minimizes human errors and strengthens safety governance.

-

How does viAct’s latest Conversational AI feature enhance the Permit to Work (PTW) process?viAct’s latest Conversational AI feature revolutionizes the PTW process by enabling voice and chat-based interactions for seamless permit management. Workers and supervisors can now: • Request and approve permits using natural language via voice commands. • Get real-time AI chat assistance for compliance checks, risk assessments, and permit validation. The LLM powered virtual assistant by viAct makes EHS/ Safety Managers easy with the PTW process more efficient, user-friendly, and accessible, reducing delays and improving safety compliance.

-

What is the accuracy of viAct’s scenario-based AI for environmental monitoring?viAct’s video analytics powered scenario-based modules for environmental monitoring have been backed by strong R&D to achieve an exceptional accuracy of 95-98%.

-

What are the pre-requisites for deploying viAct’s video analytics solution for environmental monitoring?viAct is known for its simple plug & play AI powered video analytics which can be deployed in any critical jobsite to comply environmental monitoring. The only requirement is: ✅2MP IP camera with RTSP link ✅Internet & Electricity Connectivity ✅viAct’s AI Modules

-

What are viAct’s AI powered modules for environmental monitoring?viAct’s AI powered modules for environmental monitoring are those that helps jobsites to comply with environmental regulations such as Water Pollution Detection, Urban Flood Prevention, Illegal Dumping Detection, Dump Truck Management, Construction Material Classification, Construction & Demolition Waste Management, Air Quality Detection, and many more.

-

Why AI is important for environmental monitoring in critical jobsites?Artificial Intelligence (AI) and its subsets like video analytics help to ensure compliance with environmental plans, permits and regulations. Also, it becomes quite impossible to manually monitor these compliances in huge jobsites like construction, mining, manufacturing, oil & gas industries. Thus, AI augments environmental monitoring by mitigating and minimizing environmental impact with stringent surveillance.

-

How viAct helps in improving ESG scoring of any project?The video analytics powered modules of viAct are bifurcated into three segments viz. Safety, Productivity & Environmental. 🚨The safety modules help to improve “Social” factor by protecting lives of workers in jobsites through safety alerts. 💡The productivity module helps in keeping a track of progress automatically by bringing a transparent error-free workflow with an intuitive dashboard to promote “Governance” factor. 🌿The “Environmental” factor is improved by the environmental modules which are designed to cover various applications including waste classification, pollution detection etc. Thus, boosting ESG scoring of any project in a holistic manner.

-

What is the pricing for viAct’s AI powered environmental monitoring?The pricing starts with USD 200 per camera per module per month. However, pricing may vary according to project size and user requirements. (Bulk Discounts Applicable)

-

Is there a learning curve for site personnels to effectively use Construction Data Management Portal (CDMP) of viAct’s 4S construction system?The Construction Data Management Portal (CDMP) & the Centralized Management Platform (CMP) of viAct’s 4S system is designed with an intuitive interface, ensuring there's no significant learning curve for site personnel. Its user-friendly dashboard offers clear, easy-to-understand visuals and functionalities, allowing seamless navigation and quick comprehension, eliminating the need for extensive training or specialized expertise.

-

How accurate and reliable is viAct’s SSSS Construction system in providing digitalized PTW solution as compared to traditional methods?viAct’s SSSS Construction system offers a significantly higher accuracy and reliability in providing digitalized Permit-to-Work (PTW) solutions as compared to traditional methods. By leveraging AI video analytics for real-time risk assessment and automated authorization processes, the AI powered workflow based digital PTW minimizes human error, expedites approvals, ensures compliance, and enhances overall safety protocol adherence, markedly surpassing the efficacy of manual PTW systems.

-

How does the viAct’s AI-powered Smart Site Safety System (4S) enhance safety measures on construction sites?The AI-powered Smart Site Safety System (4S) in Hong Kong revolutionizes construction site safety by employing advanced AI algorithms to detect and predict potential hazards in real time. Through constant monitoring of site activities, the centralized management platform (CMP) helps in swiftly identifying risks, enabling proactive interventions and fostering a culture of preventive safety measures thereby significantly reducing accidents and ensuring worker well-being.

-

Which other industries can use viAct’s 4S construction system to detect and prevent potential worksite hazards?4S construction system by viAct has adaptable AI-powered hazard detection capabilities that extends beyond construction and real-estate, benefiting industries like manufacturing, logistics, mining, and oil and gas. The smart features of viAct’s SSSS Construction like the Construction Data Management Portal (CDMP), the Centralized Management Platform (CMP), Digitalized Permit-to-Work (PTW), Digital Works Supervision System (DWSS) helps in proactive risk identification and prevention mechanisms through instant reporting and record keeping despite of complex operational environments, reducing accidents and ensuring worker safety across diverse sectors.

-

What are the installation requirements for viAct’s 4S construction Software?The 4S construction software by viAct is extremely easy to install. viAct’s scenario-based AI could be connected to existing CCTVs just with the RTSP link. It is designed in a way that anyone with minimal to no expertise in AI can install and use viAct’s 4S construction system in a simple plug & play manner.

-

Is Digital Permit-to-Work (ePTW) a feature of drilling rig monitoring software?Yes, the Digital Permit-to-Work is an exclusive feature of drilling rig monitoring software ensuring that only authorized and trained individuals can access high-risk red zones. Access is granted through real-time verification of digital permits, reducing the risk of unauthorized entry and enhancing overall safety protocols.

-

What is Red Zone Monitoring in drilling operations?Red Zone Monitoring refers to the surveillance and management of high-risk areas within drilling rigs where interactions between personnel and machinery occur. Effective monitoring in these zones is crucial to prevent accidents and ensure the safety of the crew.

-

Can viAct's Red Zone Monitoring system integrate with existing rig infrastructure?Yes, the system is designed for seamless integration with current CCTV and monitoring infrastructures. This ensures enhanced functionality without the need for significant changes to existing setups.

-

What role does Generative AI play in viAct's red zone monitoring system?Generative AI analyzes historical incident data to identify patterns and trends within red zones. It provides proactive recommendations for better management and prevention of future incidents, contributing to continuous improvement in safety measures through viGent Safety Chatbot.

-

What benefits can be expected post-deployment of viAct's Red Zone Monitoring system?Post-deployment, organizations can expect a holistic view of risks on the drilling floor, improved regulatory compliance in red zones, and enhanced drilling operation efficiency. The system aims to achieve higher operational excellence with lower incident rates.

-

What are the key features of viAct's Drilling Rig Monitoring Software?viAct's monitoring software offers several key features: Real-Time Hazard Detection: Identifies potential dangers such as unauthorized entry into red zones, equipment malfunctions, and unsafe behaviors. AIoT Integration: Combines IoT sensors and AI-powered cameras to monitor high-risk areas, ensuring comprehensive surveillance. Digital Permit-to-Work System: Manages access control by ensuring only trained and authorized personnel can enter designated red zones. Generative AI Dashboard: Provides an intuitive interface for incident logging and analyzes historical data to offer proactive safety recommendations.

-

How does the drilling rig monitoring software by viAct improve operational efficiency on drilling rigs?By minimizing incidents through real-time hazard detection and alerts, viAct's drilling rig monitoring software reduces downtime associated with accidents. This leads to heightened drilling efficiency and improved uptime, ensuring smoother operations.

-

Is remote monitoring possible with viAct's Red Zone Management system?Yes, remote stakeholders can access the intuitive dashboard to monitor real-time data, diagnose issues, and provide guidance to on-site personnel. This facilitates efficient collaboration and enhances overall rig safety management.

-

How does viAct's Red Zone Management system enhance safety on drilling rigs?viAct's Red Zone Management system utilizes advanced computer vision and AI technologies to detect potential hazards in real-time. By analyzing movement patterns and behaviors of drillers and crew members, the system provides instant alerts, enabling immediate corrective actions to prevent accidents.

-

How does the red zone management system by viAct detect equipment malfunctions?The red zone management system by viAct employs real-time monitoring to identify anomalies such as overheating, leaks, or abnormal vibrations in equipment. Immediate alerts are generated, allowing for swift intervention to prevent accidents and maintain operational continuity.

-

How does the Oil Field Project Control Center improve safety in oil and gas operations?The Oil Field Project Control Center provides AI-powered safety monitoring, PPE compliance detection, hazardous zone tracking, and workforce efficiency analytics. It helps prevent accidents and ensures compliance with industry regulations.

-

How does the Construction Project Control Center enhance site management?The Construction Project Control Center allows stakeholders to monitor safety, workforce productivity, and compliance in real-time. It uses AI-driven video analytics to detect potential hazards, unsafe behaviors, and inefficiencies, ensuring proactive decision-making.

-

What is viAct’s Project Control Center (PCC)?viAct’s Project Control Center (PCC) is an AI-powered centralized monitoring platform that enables real-time oversight of multiple construction and industrial sites. It integrates data from on-site cameras and IoT devices to provide actionable insights for safety, compliance, and operational efficiency.

-

What industries can benefit from viAct’s Project Control Center (PCC)?The Project Control Center (PCC) is ideal for industries like construction, oil and gas, manufacturing, and logistics. It enhances safety, compliance, and operational efficiency in complex, multi-site projects.

-

How is the Oil Field Project Control Center deployed?The Oil Field Project Control Center can be deployed using cloud-based, on-premises, or hybrid solutions, depending on the project’s security and infrastructure requirements. Check out our 5 Minute Guide AI Hosting: Cloud, On-Prem & Hybrid: Which One to Choose?

-

Can the Project Control Center (PCC) integrate with existing site cameras and IoT devices?Yes, the Project Control Center (PCC) is compatible with existing IP cameras and IoT sensors, enabling seamless integration and real-time monitoring without requiring additional hardware investments.

-

Does the Construction Project Control Center offer automated alerts?Yes, the Construction Project Control Center generates instant alerts for safety violations, unauthorized access control, and non-compliance incidents, helping site managers take immediate corrective actions.

-

How does the Project Control Center (PCC) improve productivity?The Project Control Center (PCC) automates monitoring, reduces manual site inspections, and provides AI-driven analytics, leading to better resource utilization and higher efficiency.

-

What is the ROI of implementing the Construction Project Control Center?The Construction Project Control Center significantly reduces safety incidents, improves compliance rates, and minimizes downtime, leading to cost savings and increased project efficiency.

-

Can DWSS be customized for different construction projects?Absolutely! DWSS is highly customizable and can be tailored to suit the specific needs of various construction projects, whether small-scale or large-scale. Its flexible features, such as Cleansing Inspection Checklists and Site Diary, adapt to unique project requirements.

-

Is training required to use DWSS?DWSS is user-friendly and intuitive, but we provide comprehensive training and support to ensure users can fully leverage its features, such as RISC, Site Diary, and Cleansing Inspection Checklists, for optimal results.

-

How does DWSS simplify Labour Return Records?DWSS simplifies Labour Return Records by digitizing the process of tracking worker attendance, hours, and tasks. This feature ensures accurate payroll processing, compliance with labor laws, and efficient workforce management.

-

How does DWSS handle Site Safety Inspection Records?DWSS automates the creation and management of Site Safety Inspection Records, ensuring that all safety protocols are followed. It allows users to record inspections, flag issues, and generate reports, promoting a safer work environment.

-

What is the Digital Works Supervision System (DWSS)?The Digital Works Supervision System (DWSS) is a cutting-edge construction software designed for efficient data management in Hong Kong. It streamlines processes like RISC (Request for Inspection/Survey Check), Site Diary management, Site Safety Inspection Records, Cleansing Inspection Checklists, and Labour Return Records, ensuring compliance and productivity on construction sites.

-

How can I get started with DWSS?To get started with DWSS, visit www.viact.ai/digital-works-supervision-system and request a demo. Our team will guide you through the setup process and show you how DWSS can transform your construction site management.

-

How does DWSS benefit contractors and supervisors?DWSS benefits contractors and supervisors by automating workflows, reducing paperwork, and ensuring compliance with features like RISC, Site Safety Inspection Records, and Labour Return Records. This saves time, reduces costs, and improves project efficiency.

-

What is RISC in DWSS?RISC (Request for Inspection/Survey Check) is a key feature of DWSS that allows contractors and supervisors to request and manage inspections digitally. It ensures timely approvals, reduces delays, and maintains accurate records for audits and compliance.

-

How does DWSS improve data accuracy and accessibility?DWSS centralizes all construction data, including RISC, Site Safety Inspection Records, and Labour Return Records, in one platform. This reduces manual errors, ensures data accuracy, and provides real-time access to authorized users.

-

Can DWSS integrate with other construction management tools?Yes, DWSS is designed to integrate seamlessly with other construction management tools, enhancing its functionality and ensuring a smooth workflow across all platforms.

-

Can DWSS manage Site Diaries effectively?Yes, DWSS provides a comprehensive Site Diary feature that allows users to log daily activities, incidents, and progress reports digitally. This ensures accurate record-keeping, easy retrieval, and better project tracking.

-

Is DWSS compliant with Hong Kong construction regulations?Yes, DWSS is designed to comply with Hong Kong’s construction regulations. It ensures that all processes, including RISC, Site Safety Inspection Records, and Labour Return Records, meet local standards and requirements.

-

What makes DWSS different from other construction software?DWSS stands out with its focus on Hong Kong’s construction industry, offering specialized features like RISC, Site Diary, Site Safety Inspection Records, Cleansing Inspection Checklists, and Labour Return Records. Its user-friendly interface and compliance-focused design make it a top choice for contractors and supervisors.

-

How does DWSS improve construction site management?DWSS enhances construction site management by digitizing critical processes such as RISC submissions, Site Safety Inspection Records, and Labour Return Records. This reduces paperwork, minimizes errors, and ensures real-time access to data, improving overall efficiency and compliance.

-

What are Cleansing Inspection Checklists in DWSS?Cleansing Inspection Checklists in DWSS are digital templates used to monitor and ensure cleanliness and hygiene standards on construction sites. These checklists help maintain compliance with regulations and improve site conditions.

-

How does viAct’s Job Safety Analysis software improve workplace safety?viAct’s JSA software for safety management automates hazard identification, risk assessment, and mitigation strategies using AI. By integrating Job Safety Analysis (JSA) software into daily operations, organizations improve safety compliance, reduce workplace incidents, and gain real-time insights for proactive hazard control.

-

How does viAct’s Job Safety Analysis software enhance compliance?viAct’s Job Safety Analysis (JSA) software automates compliance tracking by aligning job hazard assessments with industry standards, providing real-time risk scoring, and generating audit-ready reports to improve workplace safety adherence.

-

How does viAct’s Job Safety Analysis software leverage AI for better safety management?viAct’s AI-driven JSA software utilizes computer vision and predictive analytics to detect hazards, analyze risks, and provide real-time safety insights. By integrating JHA system for safety, businesses ensure proactive safety measures and preventive risk mitigation.

-

Can viAct’s Job Hazard Analysis software integrate with existing safety systems?Yes, viAct’s Job Hazard Analysis (JHA) software seamlessly integrates with existing safety management systems, IoT devices, and compliance platforms, ensuring a unified approach to workplace safety and regulatory adherence.

-

Can viAct’s Job Safety Analysis software integrate with wearables and IoT devices?Yes, viAct’s Job Safety Analysis (JSA) software seamlessly integrates with wearables, IoT sensors, and smart safety devices. This enables real-time hazard detection, worker protection, and automated safety alerts, enhancing workplace safety using AI-driven Job Hazard Analysis (JHA) software for compliance.

-

What industries benefit from viAct’s JHA software?viAct’s AI-driven Job Hazard Analysis (JHA) and Job Safety Analysis (JSA) software are used across 16 industries, including construction, manufacturing, oil & gas, logistics, mining, automotive, aviation, pharmaceuticals, energy, maritime, railways, food processing, utilities, chemical, warehousing, and healthcare, ensuring proactive hazard management and safety compliance.

-

What types of hazards can viAct’s Job Hazard Analysis software detect?viAct’s Job Hazard Analysis (JHA) software detects physical, chemical, ergonomic, and environmental hazards using AI-powered risk assessment models. This ensures enhanced workplace safety through automated JHA software for risk mitigation.

-

Is JHA software the same as Job Safety Analysis (JSA) software?While both JHA software for workplace safety and JSA software for safety focus on risk mitigation, Job Hazard Analysis (JHA) software offers advanced AI-driven analytics for deeper hazard detection and risk assessment compared to traditional JSA systems.

-

What is viAct’s Job Hazard Analysis (JHA) software?viAct’s Job Hazard Analysis (JHA) software is an AI-driven solution designed to identify, assess, and mitigate risks to enhance workplace safety. It automates Job Safety Analysis (JSA) to enhance compliance, improve safety measures, and streamline reporting for various industries.

-

Can viAct’s Job Safety Analysis software be customized for different job roles?Yes, viAct’s Job Safety Analysis (JSA) software allows customization based on job roles, industry-specific hazards, and company policies. This allows organizations to implement targeted risk assessments and effective safety strategies using an AI-powered JSA system for workplace safety.

-

What industries can benefit from viMOV?viMOV is ideal for industries requiring hazard monitoring in confined spaces and hard-to-reach areas, such as mining, oil & gas, tunnels, silos, underground facilities, wastewater treatment plants, and chemical storage sites. Clearly it is the best edge AI device for workplace safety for hard to reach areas!

-

Does viMOV require internet or electricity to function?No, viMOV is designed to operate without electricity and internet, making it ideal for remote and hazardous environments where connectivity is limited.

-

Does viMOV support real-time alerts and reporting?Yes, viMOV provides instant safety alerts through onsite alarms and sirens for immediate response, while also sending offsite alerts via pop-ups on the viAct dashboard for remote monitoring and compliance tracking.

-

Who has developed viMOV?viMOV is developed by viAct, a leading provider of AI-powered safety and productivity solutions. It is developed as an exclusive edge AI device for workplace safety.

-

How is viMOV different from traditional cloud-based monitoring?Unlike cloud-based monitoring, viMOV uses Edge AI to process data on-premise, ensuring lower latency, enhanced security, and faster insights without reliance on internet connectivity.

-

Why is viMOV the best Edge AI device for workplace safety?By using Edge AI for hazard detection in high-risk environments, providing instant alerts and proactive risk mitigation without cloud delays, viMOV has proved itself as the best edge AI device for workplace safety.

-

What AI capabilities are embedded in viMOV?viMOV leverages Edge AI for real-time hazard detection, including PPE compliance monitoring, atmospheric condition analysis, danger zone intrusion detection, machinery-related hazard detection, fencing compliance monitoring, and solid & liquid flow detection.

-

Can viMOV be integrated with existing security systems?Yes, viMOV seamlessly integrates with CCTV cameras, IoT sensors, and other safety infrastructure, ensuring a comprehensive Edge AI powered monitoring and compliance system.

-

Who can use viMOV?viMOV is designed for EHS teams, safety managers, compliance officers, and site supervisors who need real-time Edge AI monitoring and automated reporting in challenging environments.

-

What is viMOV and how does it work?viMOV is an Edge AI powered processing device that analyzes camera feeds and IoT data locally, eliminating the need for cloud dependency while ensuring real-time safety monitoring in hard to reach areas.

-

Are there any client reviews for viAct's Behavior-Based Safety (BBS) software?Yes! Clients across industries have shared positive feedback on viAct’s Behavior-Based Safety software. viAct’s BBS software has positive review for enhancing Behavioral Safety Compliance through real-time unsafe behavior detection. Reviews also highlight improved compliance, reduced incidents, and seamless integration with safety workflows. Many have seen a significant drop in workplace risks with AI-driven monitoring and proactive safety insights.

-

What industries benefit from viAct’s Behavior Based Safety (BBS) software?viAct’s BBS software is ideal for industries where unsafe behaviour detection and behavioural safety compliance are critical. These include: Construction (fall prevention, PPE compliance, unauthorized access) Manufacturing (hand safety, machine handling, pedestrian violations) Oil & Gas (confined space safety, hazardous material handling) Mining (fatigue monitoring, hazard zone compliance) Logistics & Warehousing (forklift safety, worker movement analysis)

-

How does viAct’s Behavior Based Safety Software help in unsafe behaviour detection?viAct’s BBS software leverages AI and computer vision to continuously monitor workplaces, detecting unsafe behaviour like bypassing safety barriers, unauthorized mobile phone usage, improper PPE compliance, and fatigue-related incidents. By analyzing worker behavior patterns, the Behavior Based Safety Software triggers real-time alerts and enables behavioural safety compliance through automated corrective actions.

-

Can viAct’s Behavior Based Safety (BBS) software integrate with existing safety systems?Yes, viAct’s Behavior Based Safety Software seamlessly integrates with existing safety management systems, IoT devices, and surveillance infrastructure. The BBS software is designed to enhance behavioural safety compliance without disrupting current safety protocols. It offers API-based integrations, ensuring smooth interoperability for streamlined unsafe behaviour detection and proactive safety interventions.

-

Does the Behaviour Based Safety Software provide reports and analytics?Yes, viAct’s BBS software generates detailed reports on behavioural safety compliance, incident trends, and risk assessments. The software: Provides unsafe behaviour detection analytics using its intuitive dashboard - viHUB. Tracks compliance scores, hazard trends, and safety improvements. Delivers predictive analytics to prevent future incidents.

-

How does the Behavior Based Safety Software enhance workplace safety?viAct’s Behavior Based Safety Software minimizes workplace risks by automating unsafe behaviour detection and enforcing behavioural safety compliance. It: · Detects and prevents high-risk actions using AI. · Provides real-time alerts and incident reporting. · Analyzes worker behavior trends to predict safety hazards. · Automates safety audits and compliance tracking.

-

What is viAct’s Behavior Based Safety (BBS) Software?viAct’s Behavior Based Safety (BBS) Software is an AI-powered solution designed to identify, analyze, and prevent unsafe behaviors in the workplace. The BBS software detects real-time safety violations, enhances behavioural safety compliance, and automates reporting to improve workplace safety. It provides unsafe behaviour detection through AI video analytics, Vision AI and scenario-based analysis, ensuring proactive risk prevention.

-

What is the role of Conversational AI Chatbot in viAct’s BBS software?viAct’s Behavior Based Safety Software includes an AI-powered chatbot – viGent that provides instant safety insights, recommendations, and compliance updates. This Conversational AI chatbot assists workers in real-time by answering queries, suggesting corrective actions, and generating scenario-based risk analysis. By integrating AI-driven assistance, the BBS software enhances behavioural safety compliance and ensures quicker resolution of safety concerns.

-

What are the areas of Behavioural Safety Compliance that the BBS software detects?viAct’s Behavior Based Safety (BBS) Software monitors key aspects of behavioural safety compliance, including: Unsafe behaviour detection, such as running, jumping, or ignoring safety protocols. Unauthorized actions, like working without PPE, smoking in restricted zones, or crossing pedestrian walkways improperly. Fatigue or stress-induced incidents, identifying workers at risk of fainting or collapsing. Violence and conflicts, ensuring early intervention in workplace safety violations.

-

What all kinds of Behavioral Safety Compliances could viAct detect?viAct's AI-powered behavioral safety compliance monitoring can detect various types of unsafe behaviors at workplaces. These detections help enforce safety regulations and reduce workplace accidents. Some key behavioral safety compliance checks include: Mobile Device Usage: Using a mobile phone for calls during high-risk activities is a serious unsafe behavior that can lead to accidents and workplace hazards. AI-driven solutions play a crucial role in preventing such risks by proactively educating teams on workplace safety, promoting awareness, and encouraging safer work practices. Jumping Over Belts: Working near conveyor belts poses a serious risk of unsafe behavior, leading to potential injuries. Protex enhances workplace safety by autonomously detecting safety violations, such as jumping over belts, and triggering instant alerts to prevent accidents and ensure compliance with safety regulations. Handrail Compliance/Stairs Bannister Usage: Even a small misstep can lead to serious accidents, making behaviour compliance essential for workplace safety. Ensuring the consistent use of handrails helps prevent falls and reduces injury risks. AI-powered solutions can play a key role in tackling unsafe behaviour by continuously educating teams and reinforcing safety best practices. Grouping of Workers: A sudden surge in worker presence within a specific area can indicate an emergency or lead to accidents, making unsafe behavior a critical concern. Protex enhances behavior compliance by triggering real-time alerts when worker thresholds are exceeded, helping prevent overcrowding and reducing the risk of workplace incidents. Restricted Height: Computer vision technology enhances workplace safety by continuously monitoring restricted height areas to detect unsafe behavior and enforce behavior compliance. It generates real-time alerts and actionable insights, enabling interventions and effective management of risks while ensuring adherence to safety standards. Pedestrian Way Violation: Computer vision enhances Unsafe Behaviour Detection by monitoring pedestrian compliance with designated pathways. By analyzing video feeds, it identifies deviations from safe zones, detects violations, and alerts authorities, thereby mitigating potential accidents and ensuring safety. There are multiple other too! Get in touch with us.

-

How does the viMAC system handle restricted zones?The viMAC Edge AI device allows you to set up geo-fenced restricted zones within your operation area. Once a vehicle enters a restricted area, the system triggers an alert to warn the operator. In some configurations, the system can also automatically adjust vehicle behavior to steer clear of these zones, enhancing safety and compliance.

-

What industries can benefit from the viMAC Edge AI device?viMAC is ideal for industries with high vehicle operation zones, such as construction, logistics, mining, and manufacturing. It enhances safety on worksites, warehouses, and distribution centers by preventing vehicle-related accidents and improving overall operational efficiency.

-

How can I monitor the performance of the viMAC system?viMAC provides real-time data and reports on vehicle activity, safety events, and system performance through a comprehensive dashboard. You can track near-misses, speed compliance, and other key metrics, enabling better decision-making and proactive safety management.

-

What makes the viMAC device the No.1 Edge AI Powered Anti-Collision System for Vehicle Safety?viMAC is recognized as the No.1 solution because of its superior AI capabilities, real-time processing, and seamless integration into vehicle operations. It proactively dodges near misses, sets speed limits, and enforces restricted zone boundaries to keep the operation zone safe—because AI doesn’t rely on luck, it ensures safety.

-

How does the Edge AI Powered Anti-Collision System work?The Edge AI Powered Anti-Collision System utilizes real-time data to detect nearby vehicles and obstacles, preventing collisions before they happen. By analyzing surroundings, it can automatically apply brakes, reduce speed, and warn the driver of any imminent danger, ensuring a safe working environment.

-

Is the viMAC system easy to install on existing vehicles?Yes, the viMAC Edge AI Device can be easily integrated into most industrial vehicles without requiring extensive modifications. Our team provides installation support to ensure a seamless setup, allowing your fleet to benefit from enhanced safety features quickly.

-

What is the viMAC Edge AI Device for Vehicle Control?The viMAC Edge AI Device is a cutting-edge safety solution designed to enhance vehicle control in industrial zones. Powered by advanced Edge AI, it monitors vehicle operations in real-time, detecting potential risks and automating safety measures like speed limits and restricted area alerts to prevent accidents.

-

Can the system detect and respond to near misses?Absolutely! The viMAC device is designed to identify potential near misses in real-time, enabling it to take immediate action to prevent accidents. By analyzing vehicle proximity and surroundings, it provides automatic alerts and can activate safety mechanisms like braking to avert collisions.

-

How does the viMAC system enhance workplace safety?The viMAC system turns any industrial vehicle operation zone into a safety-first environment. By utilizing AI to monitor and control vehicle movements, it minimizes human error, prevents accidents, and enhances overall safety. Whether it’s avoiding collisions, maintaining speed limits, or keeping vehicles out of restricted areas, the viMAC system ensures compliance and safety.

-

How does viHOI function as a Hoist Monitoring System?viHOI utilizes smart cameras and AI-driven analytics to track load movements, detect unsafe behaviors, and ensure compliance with lifting protocols, making it an efficient Hoist Monitoring System.

-

Which industries can benefit from capabilities of viHOI?Industries such as construction, oil & gas, logistics, and heavy manufacturing can greatly improve operational safety with viHOI advanced Crane lifting safety solution.

-

Can viHOI be used with other lifting vehicles apart from cranes?Yes, viHOI can also support hoist-equipped forklifts, telehandlers, and other lifting equipment, ensuring a flexible Crane lifting safety solution across multiple vehicle types.

-

How does viHOI improve operator awareness during lifting operations?Hook-mounted camera of viHOI offers real-time visual alerts and alarms to operators, enhancing awareness and reducing risks during load movement.

-

How does viHOI enhance awareness on-site during lifting activities?viHOI features both hook-mounted alarms for operators and tower alarms for broader site awareness, ensuring comprehensive safety during lifting operations.

-

Does viHOI provide insights on lifting cycle efficiency?Yes, viHOI records key metrics like Lifting Cycle Timing on its dashboard, enabling data-driven decision-making for improved productivity.

-

Who developed viHOI, and what is its purpose?viHOI is an innovative solution developed by viAct to enhance lifting operations' safety and efficiency. It leverages advanced Crane Safety AI and computer vision technology to monitor, analyze, and improve hoisting activities in real-time.

-

Can viHOI be integrated with different types of cranes?Yes, viHOI is designed to integrate with various crane models, including tower cranes, mobile cranes, and gantry cranes, providing a versatile Crane Safety AI solution.

-

Can viHOI help in detecting unsafe acts near lifting zones?Absolutely! AI-driven insights from viHOI can detect unsafe behaviors such as unauthorized personnel in lifting zones, improving overall Crane Safety Management.

-

What kind of recommendations does viAct AI agent when integrated with viHOI provide?Powered by intelligent co-pilot viz. viGent, AI agent of viAct when integrated with viHOI offers real-time recommendations for optimized lifting and de-lifting operations via simple prompts.

-

Can viAct detect multiple workers and violations at the same time?Yes. viAct’s PPE Detection Safety Software can track multiple individuals simultaneously across complex job sites. It uses advanced computer vision to detect multiple PPE types per worker and identifies non-compliance for each person in the frame, even in high-density environments—without compromising speed or accuracy.

-

What types of PPE can viAct detect and which industries benefit most from it?viAct’s PPE Compliance Monitoring system can detect a wide range of gear including helmets, vests, face masks, gloves, goggles, ear protection, and safety boots. This AI solution is ideal for industries such as construction, oil & gas, logistics, mining, and manufacturing, where real-time PPE monitoring helps reduce accidents, ensure regulation compliance, and promote a safer work culture.

-

Where is viAct’s PPE Detection Software available, and is deployment easy?viAct operates across key global regions, including Hong Kong, Singapore, Saudi Arabia, United Arab Emirates (UAE), Qatar, Oman, Bahrain, Kuwait, and other GCC and Middle East markets, as well as India, Southeast Asia, Australia, Europe, and North America (Open to deploy in new locations!). Deployment is quick and seamless via RTSP integration with existing CCTV systems, with edge or cloud options for real-time monitoring.

-

How does viAct ensure real-time PPE compliance and reduce safety risks?Using computer vision and AI, viAct continuously scans CCTV feeds for PPE violations and sends immediate alerts when non-compliance is detected. This real-time PPE monitoring replaces manual safety checks, reduces human error, and enables supervisors to take proactive action. The system also tracks entries into restricted zones, making it a powerful tool for safety automation and incident prevention.

-

How does viAct help businesses improve PPE compliance rates?viAct’s AI-powered PPE Compliance Monitoring system enables real-time detection of PPE violations through existing CCTV infrastructure. By automating the safety oversight process, the system ensures that every worker is continuously monitored and save average 10000USD/Site spent on mannual inspection. It instantly flags non-compliance, provides actionable alerts, and tracks trends via our viHUB dashboard—driving higher compliance and reducing on-site risks.

-

Can PPE Detection rules be customized for different project sites?Absolutely. viAct allows full customization of PPE detection rules to match your site's unique safety protocols. Whether it's monitoring hard hats in one zone and face masks in another, our system adapts to specific PPE requirements, risk areas, and operational workflows—ensuring relevant and accurate compliance tracking for every location.

-

What is PPE Detection Safety Software and how does it work with existing CCTV systems?PPE Detection Safety Software is an AI-based tool that analyzes real-time video feeds to detect whether workers are wearing required PPE like helmets, vests, gloves, and masks. viAct’s software connects seamlessly with your existing IP CCTV infrastructure via RTSP (Real-Time Streaming Protocol), so there’s no need for new hardware. Once integrated, it monitors feeds to detect PPE non-compliance in real time and instantly alerts site managers through dashboards, email, or SMS. Understand More Here in the Video:

-

Is viAct’s PPE Detection Software compliant with international safety, privacy, and data protection standards?Yes! viAct is committed to the highest levels of safety, security, and data privacy compliance, in alignment with global standards including GDPR. Here’s how we ensure that: 1. Privacy-by-Design with GDPR alignment: Our PPE Detection Safety Software follows a privacy-first design model and complies with key GDPR principles. We blur faces and sensitive elements (e.g. number plates) using automated detection and obfuscation techniques to ensure worker anonymity and data minimization. 2. Secure cloud and edge processing: viAct uses Amazon Web Services (AWS) with encrypted storage for secure data hosting. For added privacy, our Edge AI solution processes video locally on-device, ensuring no raw visual data leaves the site unless required—minimizing exposure. Cloud, On-Prem & Hybrid deployement options are also available. 3. Privacy-Preserving AI & Machine Learning: Our models are trained using privacy-preserving deep learning methods, incorporating differential privacy techniques to protect individuals from model inversion and data leakage during inference and prediction. 4. Real-Time Data Protection through Edge AI: By running AI models on-site through edge computing, viAct avoids unnecessary cloud transfers and aligns with data minimization best practices. Only anonymized metadata is transmitted to viHUB, our centralized analytics dashboard. 5. Transparent data handling and consent protocols: We follow GDPR Article 4(11) on consent and ensure that clients are fully informed. All data used is obtained with clear permissions, with options for opt-in/out and role-based access control built into the platform. Read full safety report here: 1. PRIVACY & RESPONSIBLE AI: A guide for GDPR Compliances in Construction Technology - https://www.viact.ai/gdprinconstructiontechnology 2. The Ultimate 5 Minute Guide AI Hosting: Cloud, On-Prem & Hybrid; Which One to Choose? - https://www.viact.ai/aihostingebook

-

Does viAct provide PPE compliance reports and safety analytics?Yes. All PPE compliance trends, violation histories, and heatmaps are centralized in viHUB, viAct’s cloud-based Project Control Center. viHUB allows safety teams to access real-time dashboards, generate reports, and analyze safety data across multiple sites. These insights help in optimizing safety protocols, planning training sessions, and passing audits with ease.

-

How much time does it take for viAct to deploy its PPE Detection Software?viAct’s PPE Detection Software can be deployed within 1 to 5 business days, depending on the site size and deployment type (Cloud, Edge, or Hybrid). Since the system connects seamlessly with existing CCTV infrastructure via RTSP, there's no need for new hardware in most cases. For sites opting for Edge AI deployment, plug-and-play viMAC devices are shipped pre-configured, enabling rapid on-site activation. Our team also provides remote or on-site support for smooth onboarding and integration into viHUB for analytics and reporting.

-

Can it track and analyze safety performance metrics?Yes, Health and Safety Management Software can track and analyze safety performance metrics using Computer Vision, Edge AI, and IoT integration. It continuously monitors workplace activities, detecting safety violations, PPE compliance, near misses, and hazardous behaviors in real time. AI-powered dashboards aggregate data from video analytics, sensors, and historical incident reports to generate key safety performance indicators such as incident rates, compliance trends, and risk heatmaps. Generative AI enhances predictive analytics by identifying patterns in unsafe behaviors and recommending proactive interventions. This data-driven approach enables organizations to optimize safety protocols, ensure regulatory compliance, and reduce workplace incidents.

-

What role does IoT play in safety monitoring?IoT plays a crucial role in safety monitoring by integrating smart devices and sensors to detect hazards, automate responses, and enhance real-time decision-making. Smart helmets and smartwatches track worker vitals, detect fatigue, and send distress signals in emergencies. Smart locks and access control systems restrict unauthorized entry to hazardous areas. Gas leak detectors and weather stations monitor air quality, temperature fluctuations, and toxic gas levels, preventing fire and explosion risks. Fleet tracking systems improve vehicle safety by monitoring driver behaviour and preventing collisions. Combined with Computer Vision and Edge AI, IoT ensures proactive risk detection, compliance enforcement, and workplace safety.

-

What is viAct Health and Safety Management Software?Health and Safety Management Software by viAct is an AI-driven safety solution that automates workplace safety processes, monitors hazards, and ensures compliance with industry regulations. It integrates Computer Vision, Edge AI, IoT, and Generative AI to enhance risk assessment, incident prevention, and compliance reporting in real-time.

-

What industries benefit from Health and Safety Management Software?viAct Health and Safety Management Software benefits a wide range of industries, particularly those with high-risk environments, compliance requirements, and workforce safety concerns. Key industries include: Construction, Manufacturing & Industrial Plants, Oil & Gas, Mining, Logistics & Warehousing, Healthcare & Pharmaceuticals, Aviation, Power & Utilities, and Automotive & Transportation.

-

What are the core capabilities of viAct’s Health & Safety Management Software?viAct’s Health & Safety Management Software is built with a suite of advanced, AI-powered modules to comprehensively manage and automate workplace safety. The core capabilities include: Job Hazard Analysis (JHA) Software Automates Job Safety Analysis (JSA) with AI-powered risk assessments, ensuring compliance and proactive hazard control. Incident Management Software Uses computer vision and edge AI to detect, log, and analyze incidents, helping reduce Lost Time Injury Frequency Rate (LTIFR). Lone Worker Monitoring System Protects isolated or remote workers via real-time video analytics and IoT tracking, triggering immediate alerts during emergencies. Vehicle Control Management Software Monitors and evaluates industrial vehicle behavior using video analytics to improve performance and operational safety. Behaviour-Based Safety (BBS) Software Detects unsafe actions and enforces behavioral compliance using real-time AI-powered observations and alerts. Scaffolding Safety Software Digitizes scaffold inspections and automates safety checklists, ensuring structural safety and compliance at every stage. Housekeeping Assessment Software Solution Monitors cleanliness, detects clutter, and maintains hygiene standards through real-time AI-powered housekeeping assessments. Crane Safety Software Tracks load alignment, lifting behavior, and operational patterns using video analytics to prevent accidents and enable predictive maintenance. Ergonomics Assessment Software Performs REBA/RULA-based posture assessments via computer vision to reduce Musculoskeletal Disorder (MSD) risks. Forklift Safety System Enables real-time collision detection and avoidance with edge-AI, protecting workers and machinery in high-traffic environments. Area Control Safety System Prevents unauthorized access by monitoring restricted zones, detecting intrusions, and alerting security in real time.

-

Does the software support real-time alerts and incident reporting?Yes, the Health and Safety Management Software by viAct supports real-time alerts and incident reporting through advanced AI-driven technologies. Computer Vision continuously analyzes live video feeds to detect safety violations and hazardous behaviours, triggering instant alerts for immediate corrective actions. Edge AI ensures low-latency processing by analyzing data directly on-site, enabling real-time detection of risks such as falls, equipment malfunctions, and unauthorized access. Additionally, IoT integration connects with smart sensors and wearables to monitor environmental hazards like gas leaks, abnormal temperature fluctuations, and excessive noise, sending automated alerts to EHS teams. The software also features a centralized dashboard that streamlines incident reporting, ensuring compliance, documentation, and data-driven decision-making.

-

Where is viAct’s Health and Safety Management Software currently deployed or available?viAct’s Health and Safety Management Software is available globally, with a strong presence across Asia-Pacific (Hong Kong, Singapore, India, Japan), the Middle East (UAE, Saudi Arabia, Qatar), and expanding across Europe (Germany, UK, Spain) and North America (USA, Canada). It is deployed at diverse sites including construction megaprojects, manufacturing plants, oil & gas fields, logistics hubs, and smart cities. The solution is accessible via desktop and mobile and integrates with existing CCTV and IoT infrastructure for quick deployment.

-

What is a Video Analytics Solution and how does it work with existing CCTV systems?A Video Analytics Solution is an AI-powered system that analyzes real-time video feeds to detect safety incidents, operational inefficiencies, and compliance issues using computer vision. viAct’s solution integrates effortlessly with your existing IP CCTV infrastructure via RTSP (Real-Time Streaming Protocol), requiring no new hardware. Once connected, it continuously monitors camera feeds to identify unsafe behaviors, PPE violations, equipment misuse, and more — triggering real-time alerts via dashboard, email, or SMS to help safety teams respond instantly.

-

Where is viAct’s Video Analytics System available, and is deployment easy?viAct’s Video Analytics System is available across major global regions — including Hong Kong, Singapore, Saudi Arabia, UAE, Qatar, Oman, Bahrain, Kuwait, and other GCC countries, as well as India, Southeast Asia, Australia, Europe, and North America. Deployment is quick and seamless through RTSP integration with existing CCTV infrastructure. With flexible Edge and Cloud options, the system enables real-time monitoring without the need for new hardware. (And yes — we’re open to deploying in new locations too!)

-

How much time does it take to deploy viAct’s Video Analytics Platform?viAct’s Video Analytics Platform can be deployed within 1 to 5 business days, depending on site size and whether it's a Cloud, Edge, or Hybrid setup. The platform integrates seamlessly with your existing CCTV infrastructure via RTSP, so in most cases, no additional hardware is required. For Edge AI deployments, plug-and-play viMAC devices are shipped pre-configured for rapid on-site activation. Our team also offers remote or on-site support to ensure smooth onboarding and full integration into viHUB for real-time monitoring and analytics.

-

How does viAct Video Analytics Solution help improve PPE compliance and reduce manual inspections?viAct’s AI-powered Video Analytics Solution automates PPE compliance monitoring using existing CCTV infrastructure. It eliminates the need for manual safety checks, saving up to $10,000 USD per site in inspection costs. Real-time alerts, trend analysis, and historical reporting via viHUB help safety teams respond faster and boost long-term compliance.

-

Can viAct’s Video Analytics Solution detect multiple workers and violations at once?Yes. viAct’s Computer Vision System is capable of tracking multiple individuals simultaneously across large, high-density job sites. It detects different types of PPE per person — such as helmets, vests, or gloves — and identifies violations in real time. The system maintains high speed and accuracy, even in complex environments with overlapping personnel.

-

Can detection rules be customized for different project sites?Absolutely. viAct’s Video Analytics Platform offers full customization of PPE and safety violation rules to suit your site’s protocols. Whether you need to monitor hard hats in one zone, face masks in another, or restricted access areas — the system adapts to project-specific needs, ensuring relevant compliance enforcement across all locations.

-

What types of events can viAct’s Video Analytics Solution detect and which industries benefit most from it?viAct’s Video Analytics Solution can detect a variety of site events including PPE non-compliance, unsafe behaviors (like running or phone usage), unauthorized access, work-at-height violations, proximity hazards, and equipment misuse. This AI-powered system is ideal for industries such as construction, oil & gas, logistics, mining, manufacturing and more — where real-time video analysis enhances safety, boosts productivity, and ensures regulatory compliance.

-

Why viAct.ai is a Leading Video Analytics Solution in Hong Kong & Singapore?viAct.ai stands out as a leading provider of AI-powered video analytics in Hong Kong and Singapore, with a strong track record of real-world deployments, government adoption, and cross-departmental use across construction, manufacturing, oil & gas, and public infrastructure projects. ✅ 1. Proven Deployment Track Record viAct has achieved over 50+ deployments in both Hong Kong and Singapore, including: Infrastructure Mega Projects Public Housing & Urban Redevelopment Tunnels, Railways, and Airport Terminals Factory Floor Automation in Industrial Parks Oil & Gas Facilities and Shipyards These implementations span both public and private sectors, showcasing its scalability and adaptability. ✅ 2. Adopted by Government Bodies & Public Authorities viAct’s AI solutions are trusted by multiple government departments and public institutions, including: 🔹 In Hong Kong: Airport Authority Hong Kong (AAHK) – for airside safety & suspended load monitoring Hong Kong Housing Authority (HKHA) – for smart site safety on public housing projects Civil Engineering & Development Department (CEDD) – for slope and excavation monitoring Gammon Construction, Kum Shing, Hip Hing – deploying on government-funded infrastructure 🔹 In Singapore: Land Transport Authority (LTA) – for tunneling and MRT site safety Housing & Development Board (HDB) – for AI-driven worker safety & open-edge monitoring Building & Construction Authority (BCA) – involved via SSIC & ConTech ecosystem JTC & Industrial Parks – for real-time factory and logistics yard monitoring These agencies use viAct across safety, environmental, and productivity divisions, not just EHS. ✅ 3. Multi-Department Usage Within Enterprises viAct’s platform supports cross-functional needs: Safety Departments – real-time unsafe act detection (e.g. PPE violations, worker under suspended load) Operations Teams – productivity tracking and workflow optimization ESG & Compliance Units – automated reporting for regulatory and sustainability audits IT & Digital Innovation – integration into BIM, CDE, and Smart Control Centers This makes viAct a strategic digital enabler rather than a point solution. ✅ 4. Plug-&-Play AI Modules Built for Local Industry Needs 30+ ready-to-use AI modules including: PPE Detection, Open Edge Monitoring, Vehicle-Zone Intrusion, Unsafe Behavior Detection Trained on regional construction and industrial visuals for high accuracy in Asian worksite conditions ✅ 5. Compatible with Existing CCTV & Smart Devices Works with existing CCTV infrastructure – no need for hardware overhaul Supports edge computing via viMAC for low-latency AI Integration-ready with BIM, ERP, and cloud dashboards This ensures fast deployment and low disruption in live projects. ✅ 6. Aligned with Regional EHS Regulations Fully supports: Hong Kong’s Construction Site Safety Handbook and F&IU guidelines Singapore’s WSH Act and ConTech innovation roadmaps Helps organizations ensure regulatory compliance and reduces safety violations. ✅ 7. Driving Measurable Safety & ESG Impact Projects using viAct report: 80%+ reduction in safety incidents 30% improvement in site productivity Automated ESG documentation (e.g., man-hours, near misses, CO2 reduction via digital inspections) Summary: With over 50 successful deployments each in Hong Kong and Singapore, and adoption by government departments, contractors, and industrial parks, viAct.ai is not just a video analytics platform—it’s the backbone of smart, safe, and sustainable infrastructure development in Asia.

-

Does viAct’s Computer Vision Solution provide PPE compliance reports and safety analytics?Yes. viAct’s Computer Vision Solution centralizes all PPE compliance data, violation logs, and risk heatmaps in viHUB, the cloud-based Project Control Center. Safety teams can access real-time dashboards, generate detailed reports, and analyze safety score across multiple sites. These insights support better safety planning, targeted training, and smooth compliance during audits.

-

How does viAct’s Computer Vision System ensure real-time safety compliance and reduce risks?Using AI-powered computer vision, viAct’s system continuously analyzes CCTV feeds to detect safety breaches like PPE non-compliance, unsafe behavior, unauthorized zone entry and more. The system sends instant alerts upon detecting violations, helping supervisors act proactively. By automating manual safety checks, it reduces human error and enhances site-wide safety enforcement — making it a powerful tool for incident prevention and regulatory compliance.

-

Is viAct’s Computer Vision Solution compliant with international safety and data privacy standards?Yes. viAct is built with global compliance in mind, including full GDPR alignment. The system uses privacy-by-design principles — with features like face blurring, edge processing, encrypted cloud storage, and anonymized metadata. It supports cloud, on-premises, and hybrid deployments. Transparent data handling, consent management, and privacy-preserving AI ensure that both operational safety and data protection go hand in hand. Read full safety report here: 1. PRIVACY & RESPONSIBLE AI: A guide for GDPR Compliances in Construction Technology - https://www.viact.ai/gdprinconstructiontechnology 2. The Ultimate 5 Minute Guide AI Hosting: Cloud, On-Prem & Hybrid; Which One to Choose? - https://www.viact.ai/aihostingebook

Think Your Site is Safe?

Let our Video Analytics Software System Double-Check That!

Unlock the full potential of computer vision AI modules with viAct video analytics software.